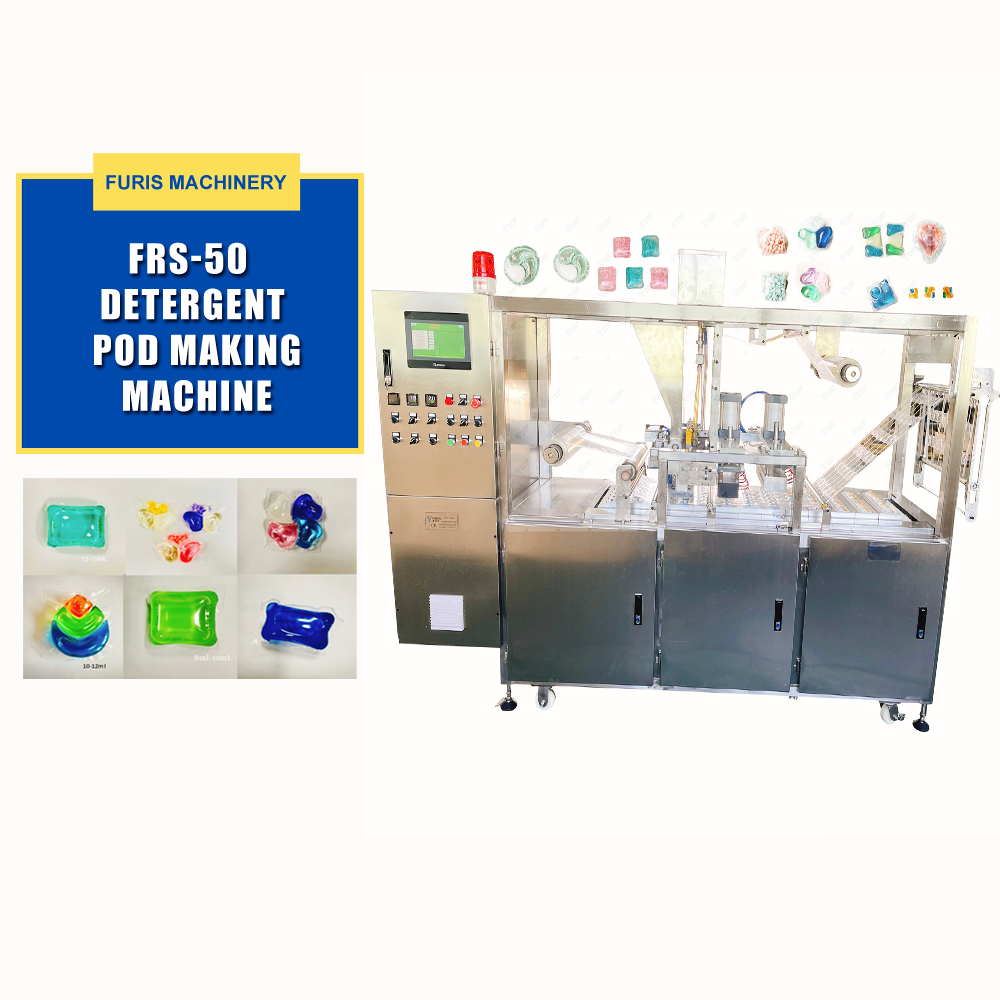

FRS-50 Detergent Powder Liquid Pod Making PVA Film Packing Machine

Sample

Working Conditions

Ambient temperature: +15 ~ +30℃ is recommended. (equipment adaptation condition: 0-40℃, specific ambient temperature should fully consider the applicable conditions for condensing beads)

Relative humidity: 30% ~ 55% no condensation (equipment adaptation conditions: 25-70%, specific use of ambient humidity should fully consider the conditions applicable to condensing beads liquid and film)

Installation conditions: indoor clean workshop with temperature and humidity control.

Product Conditions

Packaging materials: according to the shape and gram weight requirements specified by the customer.

Storage conditions for packaging materials and semi-finished products (water-soluble membrane):

Recommended temperature: +15 ~ +30℃

Recommended humidity: 30% ~ 45%

Non-condensation storage between constant temperature and humidity, according to the requirements of the film manufacturers.

Semi-finished products storage conditions:

Recommended temperature: +15 ~+30℃

Recommended humidity: 30% ~ 55% of the non-condensation temperature and humidity storage.

It is determined by the formula system of beads, which shall be implemented in accordance with the quality standard of beads of your company.

Water-soluble film for packaging:

Material: PVA/PVOH

Mask thickness: 75±5 m

Bottom film thickness: 75±5 m

Transparency according to the requirements of the bead manufacturer.

Meet the quality acceptance standard of related products.

Applicable to specific PVA water soluble film and similar grades, applicable to film size range: bottom film width 500mm; top film width 400mm; film roll diameter less than 300mm.

Applying

This PVA film packing machine is applied to the PVA water soluble film to pack the liquid detergent automatic, which can be used for packing the sticky paste detergent and detergent powder also.

Features

This machine adopts PLC, touch screen, servo motor control, the machine operation is very stable.

The machine can fill the liquid detergent or powder and form the four sides bag directly, the bag of four sides is accurate, the machine packing speed is fast and the finished bag is beautiful.

The machine adopts touch screen and PLC programmable control, photoelectric sensing.

Adopt the stable reliable electrical components, make the machine run stable and easy to operate.

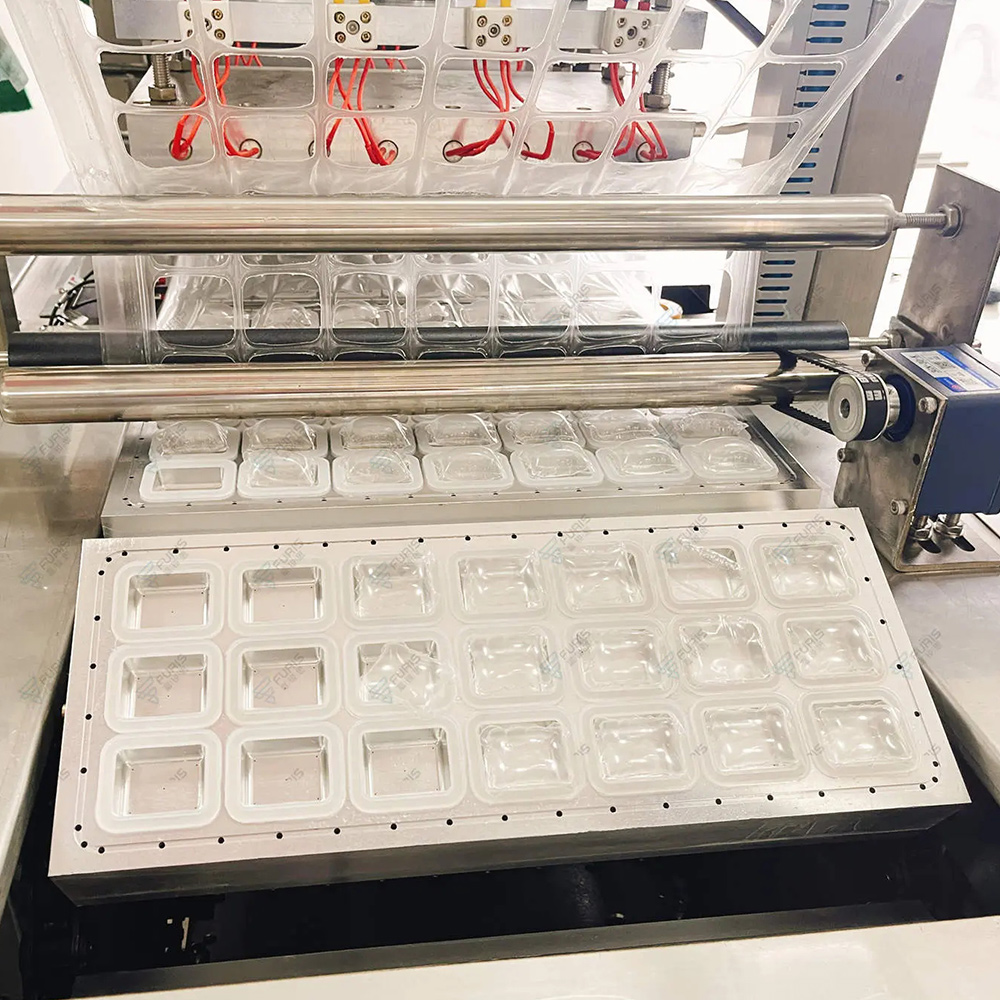

This machine adopts vacuum film absorption, multi-cavity quantitative filling at the same time, upper and lower double film water seal sealing, edge cutting with round corner hot knife, automatic decoating and beading, conveying box.

The ring is formed by self-circulating die and tooling shape flexible production line continuous production.

Through data acquisition, intelligent measurement and control and Internet of things platform technology to achieve remote production monitoring, operation and maintenance, life cycle management.

Parameter

Packing bag size |

can customize according to customer's inquiry |

Packing speed |

960-19000 pcs/hour |

The volume of packing |

3-500grams |

Measurement precision |

1.5%(will be different according to different material) |

Operation mode |

automatic cycle operation or manual single-step operation |

Control mode |

programmable controller and man-machine interface and other automation systems |

The mould number |

30+1 |

Machine power |

10KW |

Voltage |

220/380V/50HZ/60HZ 3P+N+PE |

The width of the lower film |

480mm、500mm |

The width of the upper film |

380mm、400mm |

Rack material |

304 stainless steel. |

Ambient temperature |

25℃~30℃ |

Ambient humidity |

RH50%. Refer to membrane requirements |

Air source pressure |

not less than 0.6mpa, not more than 0.8mpa |

Machine size |

4300mm*1250mm*2150mm |

Machine weight |

1000kg |

Harold Zhang(Manager)

Furis Group Co., Ltd.

Ruian Furis Import & Export Co., Ltd.

Add: Feiyun Industrial Zone, Ruian, Zhejiang, China

Tel: 0086-400-9696-598

Mob: 0086-13515779235

Email: furis@furisgroup.com

Website: www.furisgroup.com

Furis offers an excellent range of manual, semi-automatic and fully automatic machines to meet unique requirements, ensuring optimum performance and efficiency, providing an excellent solution for your shower gel pressing and packaging needs. We have a worldwide reputation as a reputable supplier of cutting-edge equipment that has been shipped all over the world. We provide OEM and distribution services to reach a wider audience and provide customized solutions to advance business operations or find new distribution channels. Contact us today to maximize your success.

Send Email

Send Email whatsapp

whatsapp